+86 4006086081

+86 4006086081

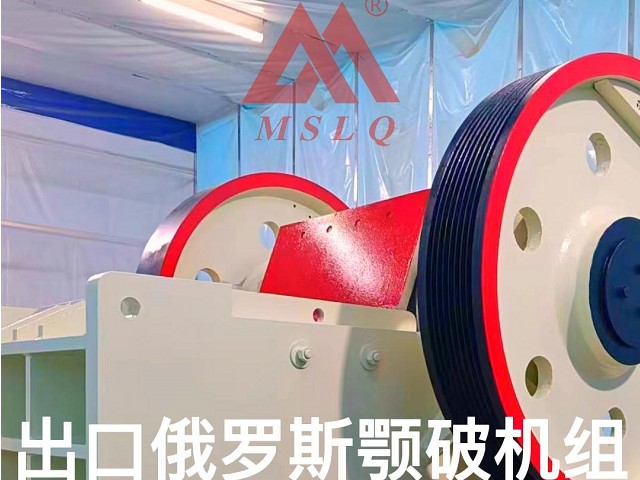

MSLQ has over 20 years’ history of designing and manufacturing crushers, and has a solid understanding of users' expectations and needs. Hundreds of jaw crushers have been produced in the past 10 years. On the basis of this deep design, manufacturing experience and extensive user feedback, a new generation of jaw crusher was developed using the most advanced computer simulation and aided design technology. Compared with the traditional jaw crusher, the new generation jaw crusher has smaller dead weight and higher strength. Its high output and low cost make PEC jaw crusher the first choice for the majority of users. The new generation jaw crusher has a nearly square large feeding port, a deep cavity and a crushing cavity design without dead zone, which improves the feeding capacity and output. A replaceable thick guard plate is installed on the top of the movable jaw to protect the movable jaw from the impact of the feeding material, so that there is no need to install a baffle plate above the movable jaw at the feeding port, and the bulk materials entering the crusher can fall directly into the crusher. The active area of the crushing chamber. The traditional jaw crusher adopts an asymmetric crushing cavity design, and its effective feed opening size is smaller than the rated opening. This series of crushers adopts a symmetrical crushing cavity design, which makes the actual opening equal to the rated opening and improves the feeding capacity.

Features:

The design of the box-shaped structure of the movable jaw and the fixed jaw, the box-shaped beam structure has 70% higher strength and 40% higher rigidity than the open structure with the same outline size and the same weight, and the equipment operation reliability is greatly improved.

The bearing of the jaw crusher is the core component of the jaw crusher. How the bearing is used will directly affect the use function of the equipment. We use imported bearings.

working principle:

When working, the motor drives the belt and pulley, and moves the movable jaw up and down through the eccentric shaft. When the movable jaw rises, the angle between the toggle plate and the movable jaw becomes larger, thereby pushing the movable jaw to approach the fixed jaw, and the material is crushed at the same time. Or split, to achieve the purpose of crushing; when the movable jaw goes down, the angle between the toggle plate and the movable jaw becomes smaller, the movable jaw plate leaves the fixed jaw plate under the action of the pull rod and the spring, and the crushed material flows down from the crushing cavity. The outlet is discharged, so as to meet the requirements of crushing materials.

Technical Parameter

| Model | Feed Opening Size(mm) | Max. Feeding Size(mm) | Discharge Setting(mm) | Capacity(t/h) | Power(kw) | G.W(ton) | Dimension(mm) |

| PEC-80 | 850x510 | 425 | 40-175 | 65-280 | 75 | 8.9 | 2725 x2040x1910 |

| PEC-100 | 1000x760 | 630 | 70-200 | 150-350 | 110 | 21.39 | 3760 x2280x2080 |

| PEC-125 | 1250x950 | 750 | 100-250 | 290-500 | 160 | 47.41 | 4210 x2775x3265 |

| PEC-145 | 1500x1070 | 850 | 125-300 | 385-800 | 200 | 59.25 | 4735 x2995x3685 |

| PEC-160 | 1600x1200 | 1000 | 150-300 | 450-1200 | 250 | 95.94 | 5790 x3275x4680 |