+86 4006086081

+86 4006086081

Aggregate production line

Sand aggregate refers to granular materials such as sand and stone mixed with cement and water when making mortar or concrete, also known as aggregate. Granular loose material that acts as a skeleton or filling in concrete. In concrete, sand and gravel account for about 3/4 of the total volume of concrete, which is divided into coarse aggregate and fine aggregate. Coarse aggregates include pebbles, gravel, waste residue, etc., and fine aggregates include medium and fine sand, fly ash, etc.

Processing Equipment

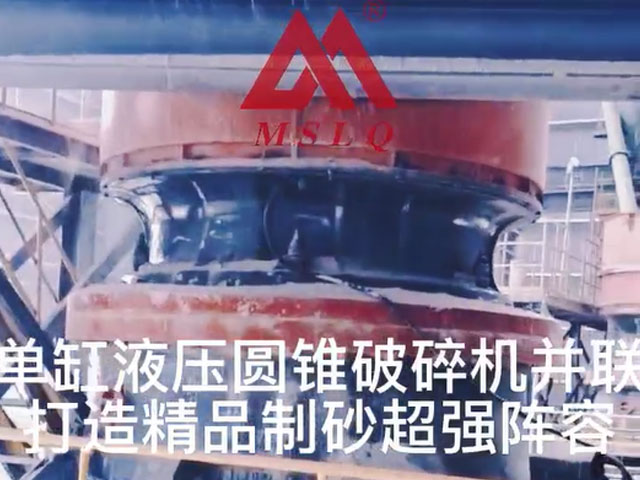

The main equipment of the sand and gravel aggregate production line are: primary crushing jaw crusher, secondary crushing impact crusher and cone crusher, followed by impact crusher or sand making machine, and finally powder mill. It plays a very important role in construction. When mixing materials, when the cement is mixed with water, it becomes a thin paste. If no aggregate is added, it will not be able to be formed and will be unusable. Therefore, in the construction industry, aggregate plays a very important role. Sand and gravel are an indispensable building material and are widely used in construction, roads, highways, railways, engineering and other fields.

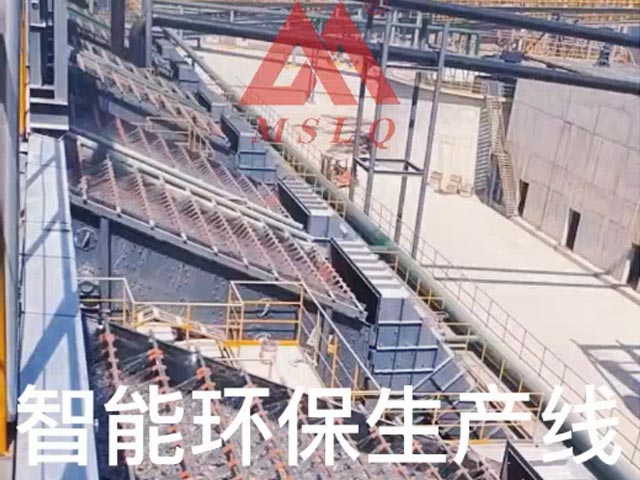

Processing system

The sand and gravel aggregate processing system can be divided into twotypes: artificial aggregate processing system and natural sand and gravel processing system. The type of sand and gravel aggregate processing system to be established is mainly selected according to the material source near the site. When the material source is sufficient and the gradation is more suitable, the natural sand and gravel aggregate processing system is generally used; when the natural aggregate source is insufficient, or the material source is sufficient but the gradation difference is large, operator needs to consider to build man-made sand making plants.